High Head Dewatering Pumps

The Remko High Head Submersible Pumps are designed for very high head pumping applications like open mine sites, underground mines, deep excavations, quarries, tunnelling and mega construction sites. Heavy-duty rugged wear resistant construction with stainless steel (SS316L) diffuser and impeller is specially designed for tough Australian mine pits with depth up to 200 metres.

Browse High Head Dewatering Pumps

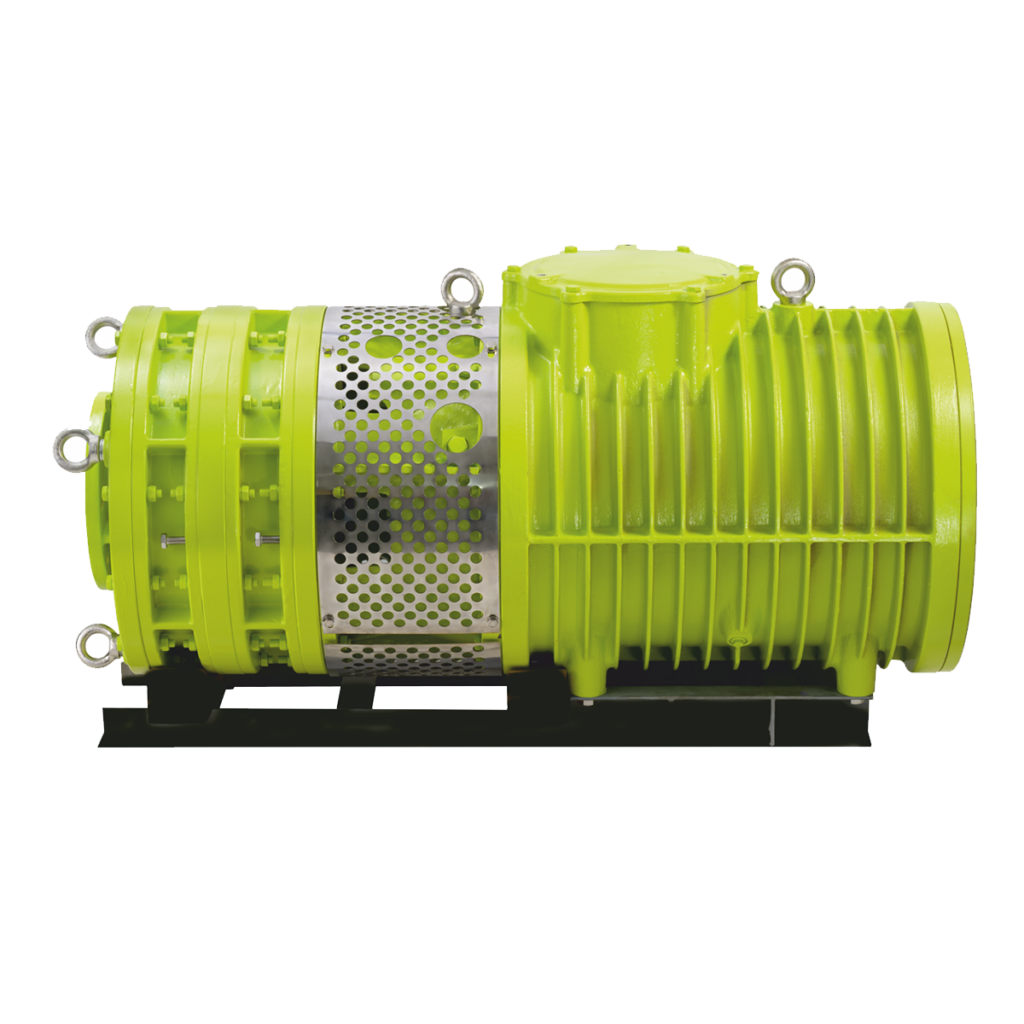

RHHS-100 - 100mm High Head Submersible Dewatering Pump

75kW Deep Pit Dewatering Pump

A powerful 75kW dewatering pump for deep pits and long-distance pipe runs with 100mm discharge, 120 m³/hr max flow, and 175m max head.

| Pump Size | 100 mm (4") |

| Flow (max) | 120 m³/hr (33.3 L/sec) |

| Head (max) | 175 m |

- Temperature Sensor for Additional Protection

- Moisture Sensor - Mechanical Seal

- 4 Bearing System

- ABB VFD based system

- Temperature relay for auto cut off

- Warrick moisture sensor / relay

- Dual class winding

- 6 wire data cable

- H07RN-F Heavy-duty Rubber Flexible Cable

- Twin Impeller & Twin Diffuser

- Twin mechanical seal (tungsten carbide)

- 10 mtr. (35mm x 4) Cable length (for DOL)

- Twin Cable optional for Star Delta

- Stainless Steel Mesh

RHHS-150 - 150mm High Head Submersible Dewatering Pump

90kW High Volume Mine Dewatering Pump

A high-volume 90kW unit for major mine dewatering and extended high-head applications with 150mm discharge, 210 m³/hr max flow, and 198m max head.

| Pump Size | 150 mm (6") |

| Flow (max) | 210 m³/hr (58.3 L/sec) |

| Head (max) | 198 m |

- Temperature Sensor for Additional Protection

- Moisture Sensor - Mechanical Seal

- 4 Bearing System

- ABB VFD based system

- Temperature relay for auto cut off

- Warrick moisture sensor / relay

- Dual class winding

- 6 wire data cable

- H07RN-F Heavy-duty Rubber Flexible Cable

- Twin Impeller & Twin Diffuser

- Twin mechanical seal (tungsten carbide)

- 10 mtr. (35mm x 4) Cable length (for DOL)

- Twin Cable optional for Star Delta

- Stainless Steel Mesh

Frequently Asked Questions

High Head Dewatering Pumps feature twin impeller and twin diffuser stages in stainless steel (SS316L), enabling discharge heads up to 198 metres. Standard dewatering submersibles typically max out around 30-50 metres head. The RHHS units also use a 4-bearing system, ABB VFD-based controls, and heavy-duty rubber flexible cable rated for demanding environments.

Other Submersible Pumps

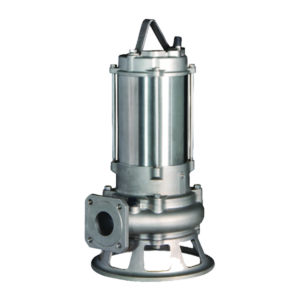

316 Stainless Steel Pumps

Corrosion Resistant

Amphibious Pumps

Wet & Dry Operation

Axial Flow Pumps

High Volume Transfer

Drainage Pumps

Groundwater Removal

Sewage Cutter / Grinder Pumps

Waste Processing

Single Channel Pumps

Large Solids Passage

Sludge/Slurry Pumps

Heavy Solids Handling

Standard Dewatering Pumps

General Purpose Use

Vortex Pumps

Non-Clog Design