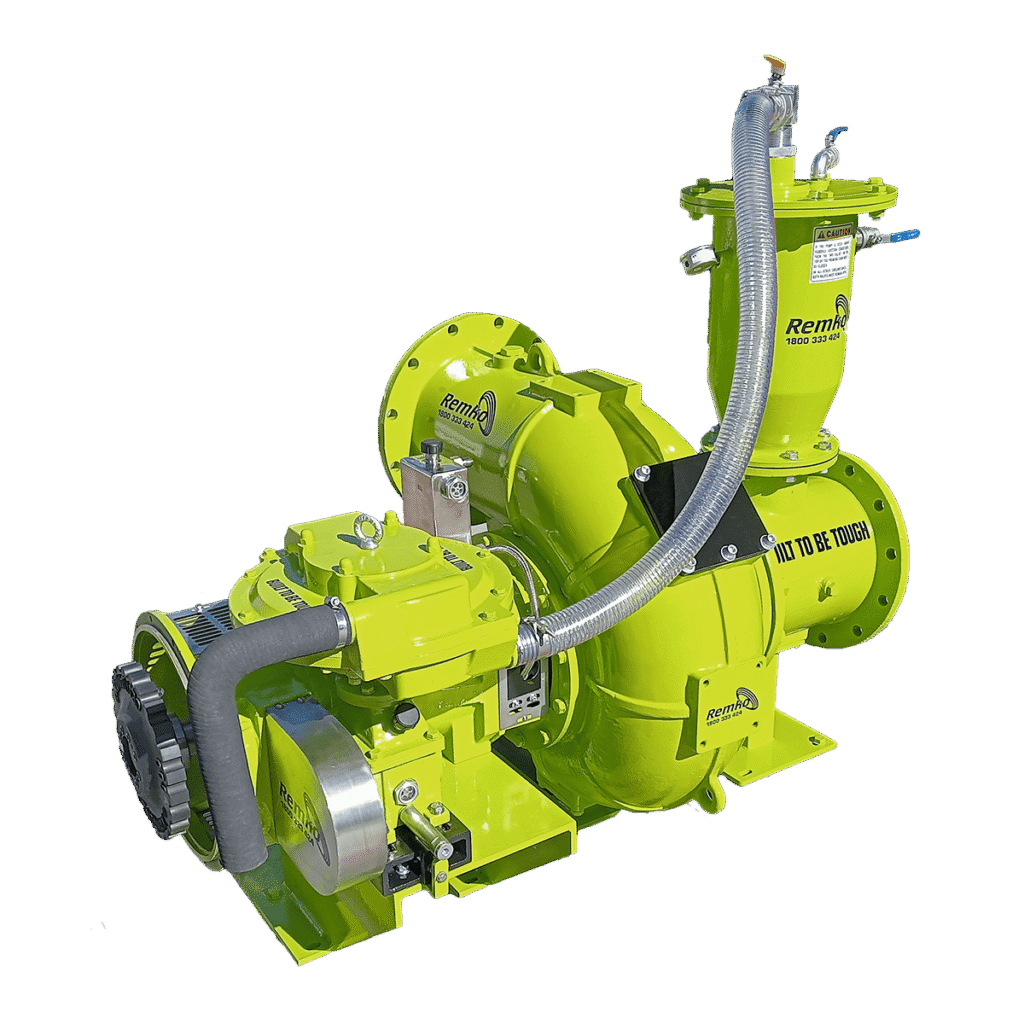

RA Series Auto Prime Pumps (Dry Prime)

Remko Automatic Dry Prime Pumps are designed for continuous, unattended operation in the toughest dewatering, construction, mining, and municipal applications. With advanced automatic priming systems, these pumps handle large suction lifts, long suction lines, and intermittent flows — all without manual intervention.

Available with two priming system options (Diaphragm or Compressor Venturi), these pumps provide flexibility for different application requirements and site conditions.

Key Features

- Automatic Dry Priming – No need for manual filling or foot valves

- Continuous Operation – Handles air, gas, or mixed flow without losing prime

- Robust Build – Heavy-duty pump casing, wear-resistant impellers, and rugged skids/trailers

- Flexible Power Options – Available with diesel engines or electric motors

- Low Maintenance – Fewer moving parts, easy service access, long life in demanding environments

Specifications at a Glance

| Pump Size | 50-250 mm |

| Flow rates | up to 1000 L/s |

| Head | up to 200 metres |

| Solids handling | up to 75 mm |

| Suction lift | up to 9 m |

| Priming | Diaphragm or Compressor Venturi system |

Choosing the Right Priming System

Feature comparison between Diaphragm and Compressor Venturi priming systems

| Feature / Benefit | Diaphragm Priming System | Compressor Venturi Priming System |

|---|---|---|

| Operating Principle | Small diaphragm pump mechanically removes air from suction line | Air compressor drives a venturi ejector to create strong vacuum |

| Priming Speed | Moderate – reliable for standard suction lengths | Fast – ideal for long suction runs and large pipes |

| Energy Use | Low – mechanically driven, minimal power required | Higher – requires compressor unit |

| Maintenance | Simple, low maintenance; occasional diaphragm replacement | Slightly higher maintenance, more components (compressor, ejector) |

| Air Leakage Handling | Continuous priming – easily handles minor leaks | Continuous priming – re-primes quickly if air enters |

| Best Applications | Construction dewatering, wellpoints, remote sites | Sewer bypass, flood control, high-capacity transfer |

| Cost | Lower upfront cost, economical choice | Higher upfront cost, but faster performance for demanding jobs |

Diaphragm Priming System

Small diaphragm pump mechanically removes air from suction line

Advantages:

- Proven, simple, and highly reliable

- Low energy consumption

- Continuous priming – capable of handling air leakage during operation

- Minimal maintenance with heavy-duty elastomer diaphragms

Best Suited For:

- Site dewatering and wellpoint applications

- Continuous duty in sandy or silty water conditions

- Remote jobs requiring a simple, self-sufficient priming system

Compressor Venturi Priming System

Air compressor drives a venturi ejector to create strong vacuum

Advantages:

- Fast priming, even on very large suction lines

- Excellent for high-capacity and long-distance suction applications

- Handles demanding conditions such as sewer bypass or flood control

- Oil-free design options available for environmentally sensitive sites

Best Suited For:

- Sewer bypass pumping

- Large-scale flood control and high-volume transfer

- Applications where rapid priming and re-priming are critical

Model Variants

Remko designs and builds Auto Dry Prime Pumps to suit a wide range of applications. The choice between solid handling pumps and clear liquid pumps depends on the type of fluid, site conditions, and performance needs.

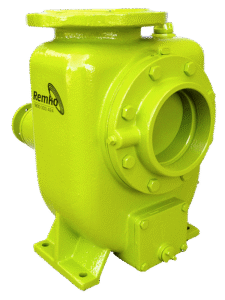

Solid Handling Pumps

Built for tough fluids with debris, grit, and solids

Features

- Large Free Passage – Impellers designed to pass solids up to 75 mm

- Heavy-Duty Materials – Wear-resistant construction for abrasive environments

- Rugged Reliability – Handles sewage, slurry, and muddy water without clogging

- Continuous Operation – Automatic re-priming ensures uninterrupted performance even with variable flow

Best Suited For

- Sewer bypass & over pumping

- Mining & quarry dewatering

- Flood control with debris-laden water

- Construction sites with dirty/silty water

Clear Liquid Pumps

Engineered for clean water transfer and high efficiency

Features

- High Hydraulic Efficiency – Optimised impeller design for maximum flow and reduced energy cost

- Corrosion-Resistant Options – Stainless steel and coated components available

- Lightweight Construction – Easier handling and transport compared to solid handling models

- Lower Operating Costs – Minimal wear when pumping clean fluids

Best Suited For

- Municipal water transfer

- Irrigation and agriculture

- Industrial water supply and circulation

- Dewatering in clean water environments

Downloads

Access product brochures, technical manuals, and specification sheets. All documents are available in PDF format for easy viewing and printing.

Brochure - Remko RA Series Pump

Manual - RA Series 1 Auto Prime Pump

Manual - RA Series 2 (LP) Auto Prime Pump

Manual - RA Series 3 Auto Prime Pump

Manual - RA Series 4 Auto Prime Pump

Manual - RA Series 5 Auto Prime Pump

Frequently Asked Questions

Remko Automatic Dry Prime Pumps are designed for continuous, unattended operation without manual intervention. The system automatically evacuates air from the suction line and pump casing, enabling the pump to handle large suction lifts (up to 9m), long suction lines, and intermittent flows without manual priming or foot valves. This ensures reliable operation even when the pump inlet is dry or above the liquid level, making it ideal for construction, mining, municipal, and disaster response applications.