When selecting and operating centrifugal pumps, one of the most critical considerations is Net Positive Suction Head (NPSH). If not properly accounted for, pumps can suffer from cavitation—a destructive condition that causes noise, vibration, efficiency loss, and serious mechanical damage.

Why This Matters

Cavitation is one of the leading causes of pump failure. It can destroy an impeller in minutes and causes significant energy loss. Prevention is essential.

What is NPSH?

NPSH stands for Net Positive Suction Head, expressed in metres of liquid. It represents the absolute pressure available at the pump suction to prevent vaporisation of the liquid.

There are two terms you’ll encounter:

NPSHa (Available)

The suction pressure that your system can deliver to the pump, based on site conditions:

- Atmospheric pressure

- Suction lift

- Liquid temperature

- Friction losses in suction piping

NPSHr (Required)

The minimum suction pressure needed by the pump to avoid cavitation:

- Determined by the pump manufacturer through testing

- Varies with flow rate

- Shown on pump performance curve

- Increases as flow increases

NPSHa must always be greater than NPSHr (with a margin of safety).

Understanding Cavitation

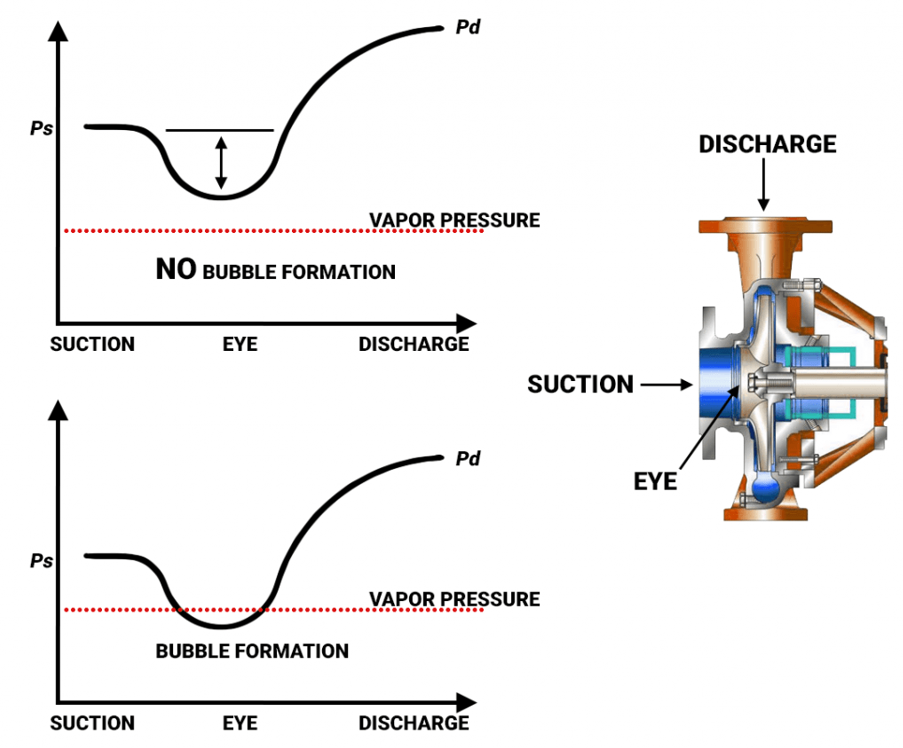

Cavitation occurs when the pressure at the pump suction drops below the liquid’s vapor pressure. This causes vapor bubbles to form inside the liquid. When these bubbles move into a higher-pressure region (such as the impeller), they collapse violently, creating micro-shockwaves.

Effects of Cavitation

Calculating NPSHa

A simplified formula for NPSHa (in metres):

NPSHa Formula

Where:

- Hatm = Atmospheric head (depends on altitude; ~10.3 m at sea level)

- Hvap = Vapour pressure head of liquid (increases with temperature)

- Hstatic = Static suction lift (vertical distance from liquid surface to pump centreline; negative if pump is above water)

- Hfriction = Friction losses in suction piping, hoses, fittings, strainers

Example Calculation

At sea level, pumping 20°C water with a suction lift of 4 m and friction losses of 1 m:

If the pump datasheet specifies NPSHr = 3 m, then operation is safe (since 5.05 > 3).

Factors Affecting NPSH

Altitude

Higher elevations reduce atmospheric pressure, lowering NPSHa.

Temperature

Hot liquids have higher vapor pressures, reducing NPSHa.

Suction Lift

The greater the vertical lift, the lower the NPSHa.

Suction Line Design

Smaller hoses, long runs, and many bends increase friction losses.

Preventing Cavitation

- Position the pump as close as possible to the water source

- Use the largest practical suction hose/pipe diameter to reduce friction losses

- Minimise suction line fittings, bends, and valves

- Keep suction hoses airtight to avoid pressure drops

- Consider submersible or vertical turbine pumps for deep suction lifts

- Always check the pump curve for NPSHr values before final selection

Rule of Thumb

A good engineering practice is to maintain:

This margin accounts for fluctuations in site conditions and helps ensure long-term pump reliability.

Summary

Key Takeaways

- NPSH is the balance between system suction conditions and pump requirements

- Cavitation is destructive and must be avoided

- Correct pump selection, proper suction design, and awareness of temperature and altitude effects are the best defences