Managing acidic trade waste requires reliable equipment, appropriate materials and effective containment. Allflo Pumps was engaged by a chemical processing facility to deliver a safe and robust solution for transferring diluted nitric acid and sulphuric acid.

The Challenge:

The system needed to pump acidic waste into a pipeline shared by multiple pumps discharging into a common header, creating risks around corrosion, pressure variation, and potential leakage. Strict safety and containment standards also had to be met.

The Solution:

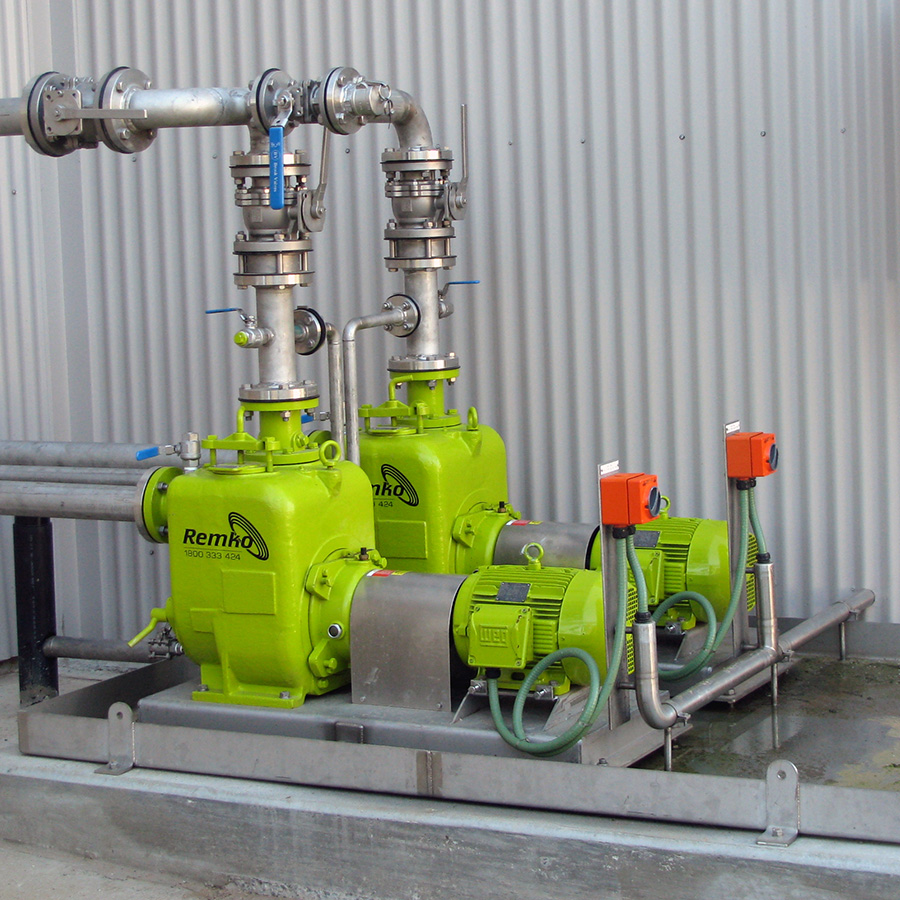

Allflo designed and manufactured a custom-engineered acid handling pumpset, tailored to the application. The solution included Remko 316 stainless steel self-priming pumps with full 316 stainless steel construction for corrosion resistance, a heavy-duty stainless steel base, installation within a stainless steel bunded area for spill containment, and custom stainless steel pipework and valves fabricated and installed on site.

Performance:

Flow rate: 18 litres per second, Discharge pressure: 220 kPa

Outcome:

This project demonstrates capability to deliver engineered pumping solutions for corrosive and high-risk trade waste applications, where safety, reliability, and material selection are critical.